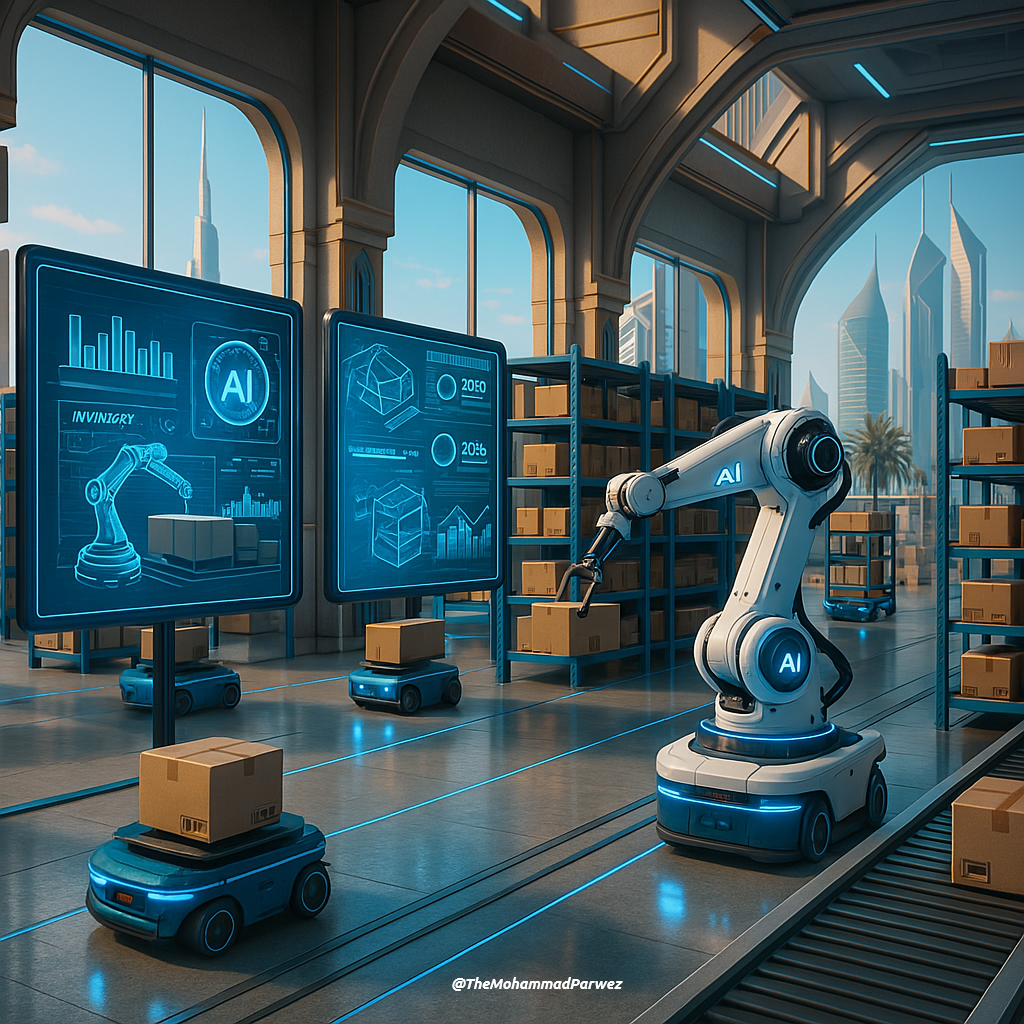

Artificial Intelligence is revolutionizing intralogistics, transforming how warehouses and distribution centers operate. From predictive analytics to autonomous systems, AI is enabling unprecedented levels of efficiency, accuracy, and cost optimization in supply chain operations. Let's explore how AI is reshaping the future of intralogistics.

1. Predictive Analytics for Demand Forecasting

AI-powered predictive analytics is transforming how warehouses anticipate and prepare for demand fluctuations. By analyzing historical data, seasonal patterns, and market trends, AI systems can:

- Optimize inventory levels: Preventing stockouts while minimizing excess inventory costs.

- Improve resource allocation: Ensuring adequate staffing and equipment during peak periods.

- Enhance supplier coordination: Providing accurate forecasts for better procurement planning.

- Reduce waste: Minimizing expired or obsolete inventory through better demand prediction.

2. Autonomous Mobile Robots (AMRs) and AGVs

AI-driven autonomous systems are revolutionizing material handling within warehouses. These intelligent machines can:

- Navigate dynamically: Using AI to adapt routes in real-time based on warehouse conditions.

- Collaborate with humans: Working safely alongside warehouse staff to optimize productivity.

- Self-optimize: Learning from experience to improve efficiency over time.

- Handle complex tasks: Performing picking, sorting, and transportation with minimal human intervention.

3. Computer Vision for Quality Control

AI-powered computer vision systems are enhancing quality control and inspection processes:

- Automated defect detection: Identifying damaged or defective products with higher accuracy than human inspection.

- Real-time sorting: Classifying products based on size, color, or other visual characteristics.

- Barcode and label verification: Ensuring accurate product identification and tracking.

- Packaging optimization: Determining optimal packaging configurations to minimize waste and shipping costs.

4. Intelligent Warehouse Management Systems (WMS)

AI-enhanced WMS platforms are providing unprecedented visibility and control over warehouse operations:

- Dynamic slotting optimization: Continuously adjusting product placement based on demand patterns and picking efficiency.

- Real-time task optimization: Assigning tasks to workers and equipment based on current conditions and priorities.

- Performance analytics: Providing insights into operational efficiency and identifying improvement opportunities.

- Exception handling: Automatically detecting and resolving operational anomalies.

5. Predictive Maintenance for Equipment

AI is transforming equipment maintenance from reactive to predictive, ensuring optimal uptime:

- Condition monitoring: Continuously analyzing equipment performance data to predict failures.

- Maintenance scheduling: Optimizing maintenance schedules to minimize disruption to operations.

- Parts inventory optimization: Predicting spare parts requirements based on equipment condition and usage patterns.

- Cost reduction: Reducing unplanned downtime and extending equipment lifespan.

🎯 Real-World Impact

Leading logistics companies implementing AI in their intralogistics operations have reported up to 40% reduction in operational costs, 60% improvement in picking accuracy, and 25% increase in overall throughput. These improvements translate directly to enhanced customer satisfaction and competitive advantage.

6. Voice and Natural Language Processing

AI-powered voice systems are streamlining warehouse operations through hands-free interaction:

- Voice-directed picking: Enabling workers to receive instructions and confirm tasks through voice commands.

- Multilingual support: Supporting diverse workforces with natural language processing in multiple languages.

- Real-time communication: Facilitating instant communication between workers and management systems.

- Training and guidance: Providing on-the-job training and assistance through voice-guided instructions.

7. Energy Optimization and Sustainability

AI is helping warehouses become more sustainable and energy-efficient:

- Smart lighting systems: Automatically adjusting lighting based on occupancy and natural light levels.

- Climate control optimization: Maintaining optimal temperature and humidity while minimizing energy consumption.

- Route optimization: Reducing energy consumption of material handling equipment through optimized routing.

- Carbon footprint tracking: Monitoring and reporting environmental impact metrics for sustainability initiatives.

Challenges and Considerations

While AI offers tremendous benefits for intralogistics, organizations must consider several challenges:

- Initial investment costs: Significant upfront investment in technology and infrastructure.

- Change management: Training workforce and adapting organizational processes to new AI-driven systems.

- Data quality and integration: Ensuring high-quality data and seamless integration with existing systems.

- Cybersecurity: Protecting AI systems and data from security threats and vulnerabilities.

The Future of AI in Intralogistics

Looking ahead, we can expect to see even more advanced AI applications in intralogistics:

- Fully autonomous warehouses: Complete automation of warehouse operations with minimal human intervention.

- Advanced robotics: More sophisticated robots capable of handling complex manipulation tasks.

- Edge computing: Real-time AI processing at the warehouse level for faster decision-making.

- Digital twins: Virtual replicas of warehouses for simulation and optimization.

Conclusion

AI is fundamentally transforming intralogistics, offering unprecedented opportunities for efficiency, accuracy, and cost optimization. Organizations that embrace these technologies today will be well-positioned to compete in the increasingly demanding logistics landscape of tomorrow.

The key to successful AI implementation in intralogistics lies in taking a strategic, phased approach that considers both technological capabilities and organizational readiness. By starting with pilot projects and gradually scaling successful implementations, companies can realize the full potential of AI in their warehouse operations.